NANOSYSTEMS: PHYSICS, CHEMISTRY, MATHEMATICS, 2018, 9 (1), P. 102–105

Composite materials using fluorinated graphene nanoplatelets

A. N. Blokhin – Tambov State Technical University, Tambov, Russia; cha-cha@rambler.ru

T. P. Dyachkova – Tambov State Technical University, Tambov, Russia

A. K. Sukhorukov – Tambov State Technical University, Tambov, Russia

D. E. Kobzev – Tambov State Technical University, Tambov, Russia

E.V. Galunin – Tambov State Technical University, Tambov, Russia

A.V. Maksimkin – Tambov State Technical University, Tambov, Russia

A. S. Mostovoy – Tambov State Technical University, Tambov, Russia

A. P. Kharitonov – Branch of the Talrose Institute for Energy Problems of Chemical Physics, Russian Academy of Sciences, Chernogolovka, Moscow Region, Russia

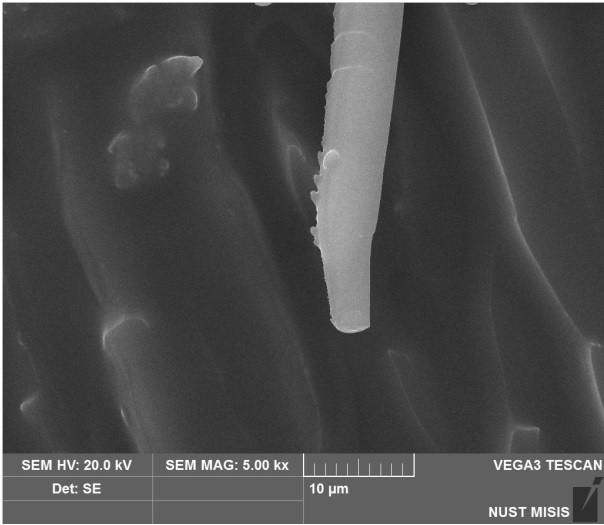

The changes occurring on the surface of graphene nanoplatelets (GNPs) during treatment with gaseous fluorine are shown. According to Raman and IR spectroscopy, C–F covalent bonds are formed. As the fluorination temperature increases, the destructive changes in the GNPs become more noticeable, as evidenced by the results of X-ray diffraction analysis and the specific surface area of the samples. The presence of fluorine-containing functional groups contributes to better dispersion of the GNPs in the epoxy matrix and to an increase in their strengthening effect. The epoxy composite containing 0.1 wt% of the GNPs treated with fluorine at 450 °C presents the maximum strength characteristics: in comparison with the unmodified material, the tensile stress increases by more than 2 times, the tensile modulus – by 20 %, the breaking stress at bending – by 80 %, and the modulus of elasticity at bending – by 60 %.

Keywords: grapheme nanoplatelets, fluorination, epoxycomposites, strength properties, reinforcement.

PACS 82.35.NP

DOI 10.17586/2220-8054-2018-9-1-102-105