NANOSYSTEMS: PHYSICS, CHEMISTRY, MATHEMATICS, 2017, 8 (6), P. 798–803

Porous polypropylene membrane contactors for dehumidification of gases

D. I. Petukhov – Department of Materials Science, Lomonosov Moscow State University, 173 Leninskiye gory, Moscow, 119991, Russia; di.petukhov@gmail.com

Ar. A. Eliseev – Department of Materials Science, Lomonosov Moscow State University, 173 Leninskiye gory, Moscow, 119991, Russia; eliseev@inorg.chem.msu.ru

A. A. Poyarkov – Department of Materials Science, Lomonosov Moscow State University, 173 Leninskiye gory, Moscow, 119991, Russia

A.V. Lukashin – Department of Materials Science, Lomonosov Moscow State University, 173 Leninskiye gory, Moscow, 119991, Russia

An. A. Eliseev – Department of Materials Science, Lomonosov Moscow State University, 173 Leninskiye gory, Moscow, 119991, Russia

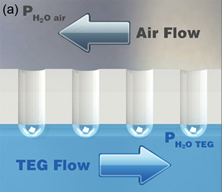

We report the application of porous polypropylene hollow fiber membranes with 100 × 500 nm slit pores in membrane contactor for air dehumidification using triethylene glycol (TEG) as an absorbent. Experiment geometry with gas flow through the lumen of fiber and absorbent circulated on the shell side was utilized to enhance water vapor stage cut. The influence of gas flow rate, liquid circulation rate and water content in triethylene glycol solution on the performance of membrane contactor was studied. The obtained results reveal that the limiting step of water vapor absorption for lumen gas flow configuration is the diffusion of water into TEG volume. Using dry TEG solution and high circulation rate the dew point of feed gas can be decreased down to ~ -30 °C for the membrane contactor performance of 30 – 60 l/(m2h), while with reducing dew point requirements to -10 °C the performance of the contactor over 1 m3/(m2h) is achievable.

Keywords: dehumidification, membrane contactor, polypropylene membrane, gas-liquid contactor.

PACS 81.05.Rm, 47.56.+r

DOI 10.17586/2220-8054-2017-8-6-798-803